Previously on youtube:

Jeremy asks: Hi Julian, thank you for this video, it’s super clear, helps me a lot to create my Airtable database to organize my nursery (I grow fruit trees). One question: in your example how would you handle it if you had different sizes for your products, such as S, M, L, XL ? I guess you would have one line per unique product, like Green T-Shirt - Size S, Green T-Shirt Size M, etc. But then I’m wondering how you’d keep things organized in the gallery view, having a card per Color / Product / Size doesn’t look optimal, it would be nice to have a small table in each card with the size and quantities. Hope I’m clear! Many thanks!

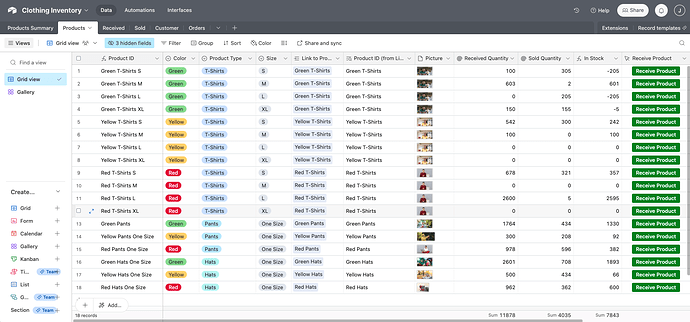

Julian answers: Hi Jeremy, very cool - I used to work in the farming world. You can achieve what you’re describing by creating what I’d call a summary table. Make a copy of the Products table with all the same fields and records, and call it ‘Product Summary’. In the original Products table, add a new line for every unique combination of size, color, type. You will still reference this table in your sold and received tables to add/remove inventory. Also in your original Products table, create a linked record field to the summary table, and then link each S,M,L etc to the correct record (which doesn’t have a size) in the Product Summary table. Now in the summary table, you can create Rollup field types that summarize inventory of each product by size using the controls in the Rollup to sum only records that are size S etc. In your gallery view, you can toggle each of those rollups on to see S,M,L etc. If you run into any issues trying this out, post some screenshots here and I’ll help you out ![]()

Jeremy: Hi Julian many thanks for your super quick and very useful answer. I gave it a go on your template, I’ll post some screenshots on the 3rings forum to make sure I understood well. I’m not native english speaker, so sometimes I may do some misinterpretation!

Also, correct me if I’m wrong, but if I want to use the same picture for a product, whatever its size, or add another kind of information that’s the same for a given product whatever its size, such as Material Composition, I should put it in the New Products Summary table, am I right? So that every time I add a new product, the main table becomes the Products Summary table.

Below : Original Products table with Size and link to Products Summary table